Introduction

Ceramic and stone tiles are durable, easy to maintain, and hygienic, representing the ideal surface coverings. However, today's lightweight construction methods can make the installation of hard surface coverings particularly challenging. In order to protect the integrity of the tile assembly, an underlayment that performs multiple functions is required.

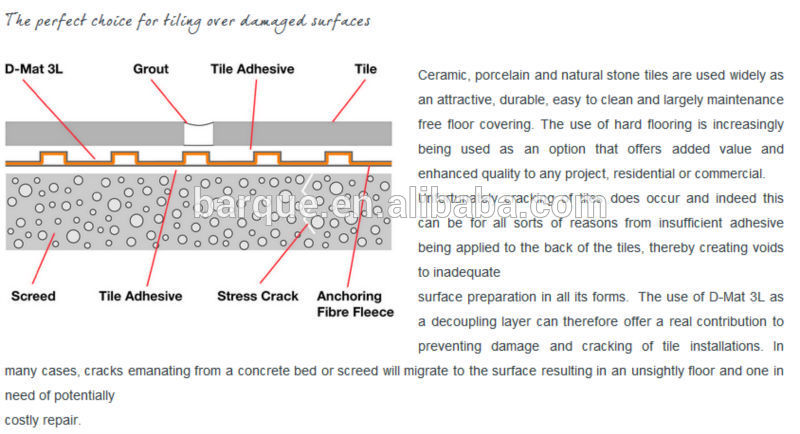

UNCOUPLING MEMBRANE is a polyethylene membrane with a grid structure of square cavities, each cut back in a dovetail configuration, and an anchoring fleece laminated to its underside. UNCOUPLING MEMBRANE is bonded to the substrate using thin-set mortar. The anchoring fleece on the underside of UNCOUPLING MEMBRANE is fully engaged in the mortar to provide a mechanical bond to the substrate. Tile is installed over UNCOUPLING MEMBRANE using the thin-bed method in such a way that the mortar becomes mechanically anchored in the square, cutback cavities of the UNCOUPLING MEMBRANE matting.

Designed specifically for ceramic tile and dimension stone installations, UNCOUPLING MEMBRANE serves as an uncoupling layer, waterproofing membrane, and vapor management layer that accommodates moisture from beneath the tile covering. Further, uncoupling membrane performs all these functions while still providing adequate support/load distribution for the tile covering.

Specification

Name | Uncoupling membrane |

Thickness | 3mm |

Color | orange and other colors available |

Package | PE film |

Uses or Functions | uses: underlayment for real wood floor, laminate floor etc

Functions: waterproof, support, uncoupling, vapor management |

Features | eco-friendly, renewable. |

Others | specific logos can be painted on our products as requested

specific products and specifications can be customized |

Function

a) Uncoupling

Tile has been successfully installed for thousands of years by incorporating an uncoupling layer, or forgiving shear interface, within the tile assembly. UNCOUPLING MEMBRANE provides uncoupling through its open rib structure, which allows for in-plane movement that effectively neutralizes the differential movement stresses between the substrate and the tile, thus eliminating the major cause of cracking and delaminating of the tiled surface.

b) Waterproofing

UNCOUPLING MEMBRANE provides reliable waterproofing in interior and exterior applications. Its polyethylene composition protects the substrate from moisture penetration, which is particularly important in today's building environment where most substrates are moisture sensitive.

c) Vapor management

The distinguishing feature of UNCOUPLING MEMBRANE is the existence of free space created by the configured channels on the underside of the matting. The free space provides a route for excess moisture and vapor to escape from the substrate that could otherwise cause damage to the tile layer above. Thus, uncoupling membrane effectively manages moisture beneath the tile covering.

d) Support/load distribution

When placed on a solid foundation, columns or pillars can support tremendous loads. The same physical principle applies to UNCOUPLING MEMBRANE installations. Column like mortar structures are formed in the cutback cavities of the matting. Loads are transferred from the tile covering through these column-like mortar structures to the substrate. Since uncoupling membrane is virtually incompressible within the tile assembly, the advantages of uncoupling are achieved without sacrificing point load distribution capabilities. The ability of uncoupling membrane installations to support and distribute heavy loads while preserving the integrity of the tiled surface has been verified through extensive laboratory and field testing, including applications exposed to vehicular traffic.